What Does it Cost?

Signet rings come in all sizes and shapes. The sky is the limit. Materials and labour dictate the value of any ring and the more we use, the higher the cost. Hollowing out a ring under the top reduces the amount of gold and lowers the cost. In our example, we reduced the price by $800 by hollowing the top out slightly. Hollowing a signet ring is fairly common, but some customers prefer a solid signet ring.

A budget of $2,000 to $3000 (Canadian) is a good plan if you are going wider and need stones. This may be a shock, but there’s no reason for me to fool around with a low-ball quote, and then try to get you to pay more after you are invested emotionally. I am not that kind of jeweller. Don’t forget, this is for a custom signet ring and it’s heavier than average.

A lower cost is possible. I can order many styles of basic signet rings at lower prices and add stones or engraved initials on them. Don’t run away if you need a basic signet ring. I know some quality ring manufacturers in Canada and I would be happy to work with you by ordering a more affordable design to use as a base.

How did I Start this Signet Ring?

One of my good customers recently contacted me to create a custom signet ring for her 65th birthday. She wanted to add three gemstones – one aquamarine and two rubies. The stones represented her and her partner’s birthstones. One more thing, she wanted the top of the ring to have a texture.

First, I needed to determine the shape, size, quality and availability of the gems. Secondly, I had to make a basic design rendering to see what the customer thinks, so I can get good feedback. If all is well, I would begin shopping for the gems I need. After a bit of further knowledge on gem prices from my supplier, I was able to firm up a price with my client.

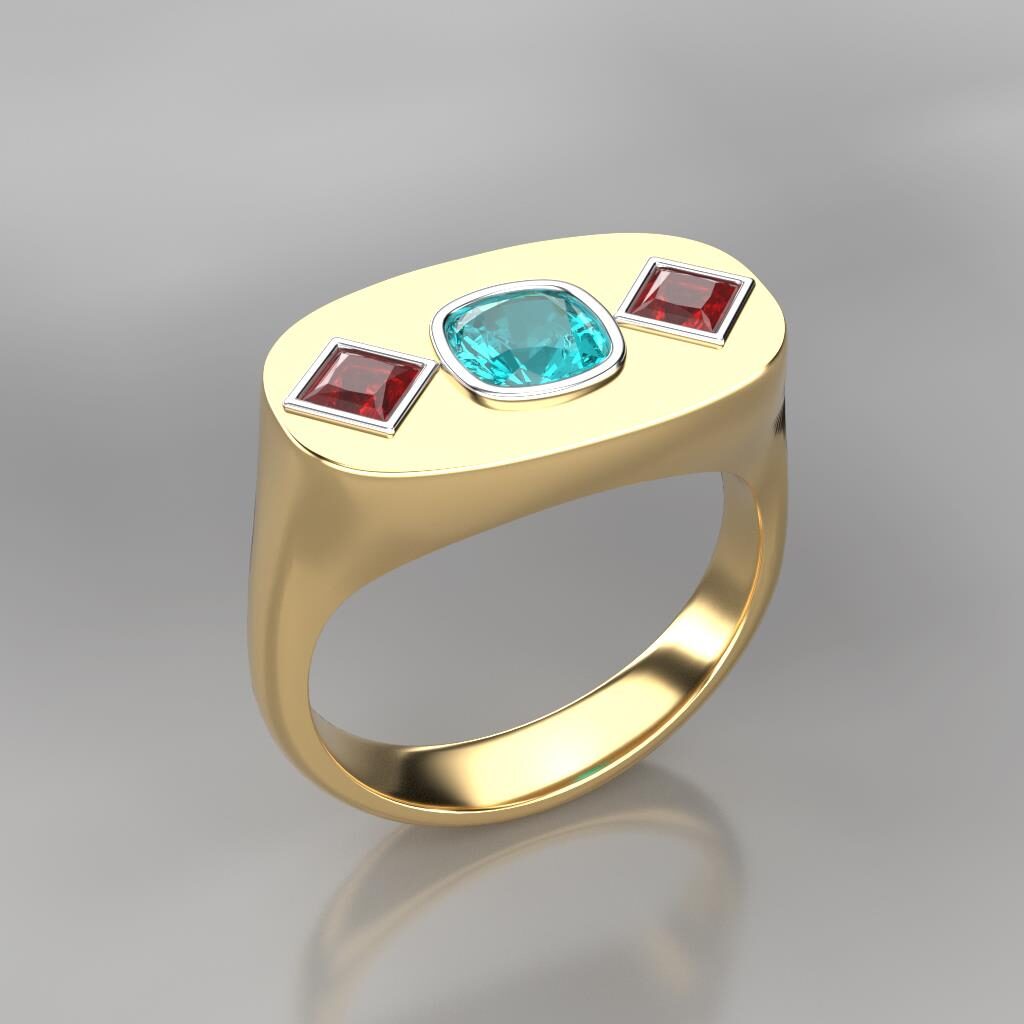

My First Design Rendering

On the first design rendering, my client was unhappy with the oval shape outline. She wanted the ring to be more angular and have diamond shape stones. I saw a new idea in my mind’s eye, so I reconstructed it.

Years ago, I would sketch designs out in a rather 2-dimensional way to convey ideas to clients. This worked well but when I created a bad sketch, I had to start again. With an investment in 3D computer design technology, I can easily back up a step and redo something to get what I want. The result is a picture perfect replica of the ring I want to make. The only thing missing is a model to try on.

Once my clients feel a design is nice, I use a 3D printer to create a resin mockup model of the ring in the correct finger size. Now my customer can see the full design, and the scale of the ring on their finger. It’s been a breakthrough in so many industries to use 3D computer design technology.

A Few More Tweaks

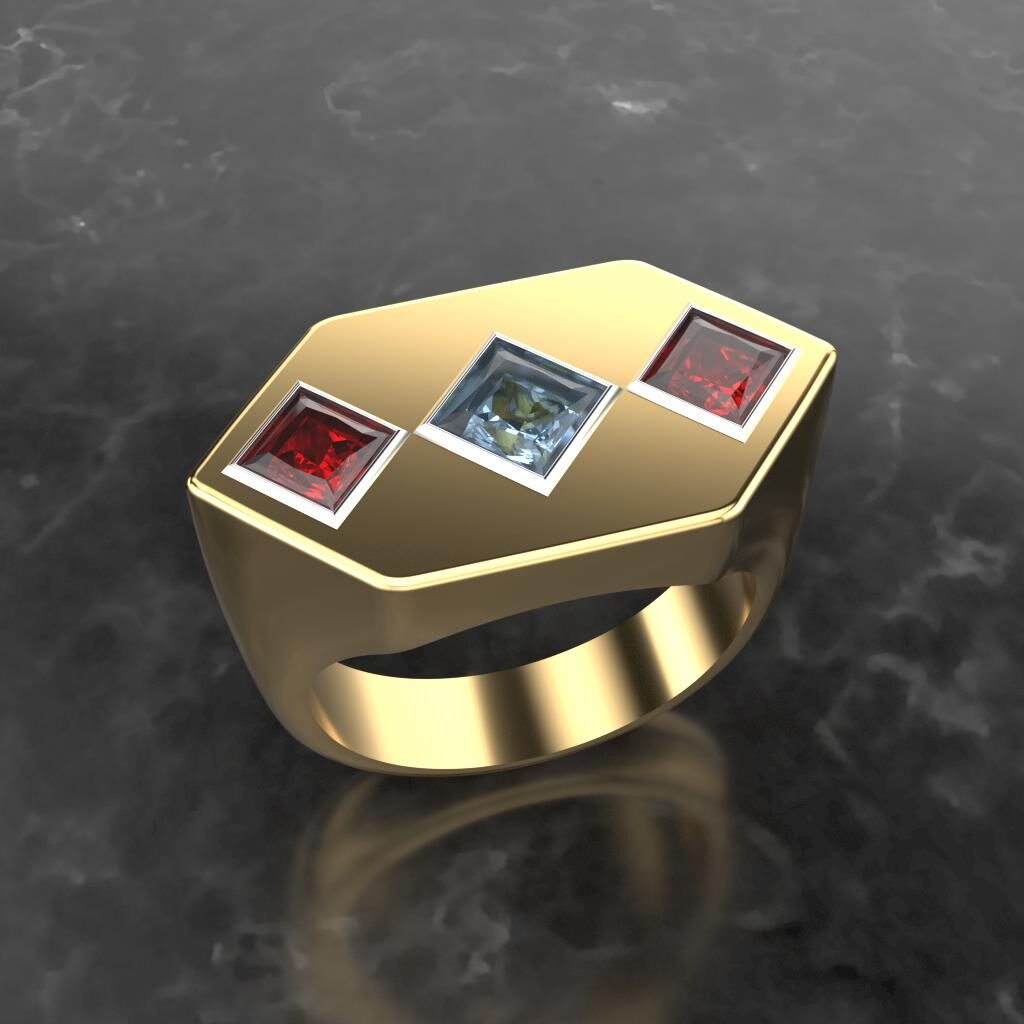

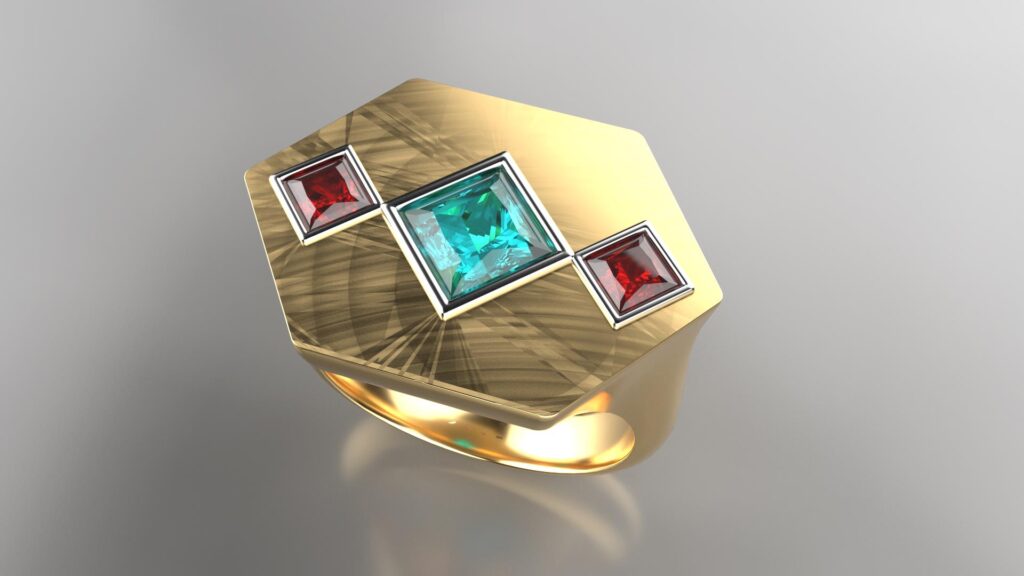

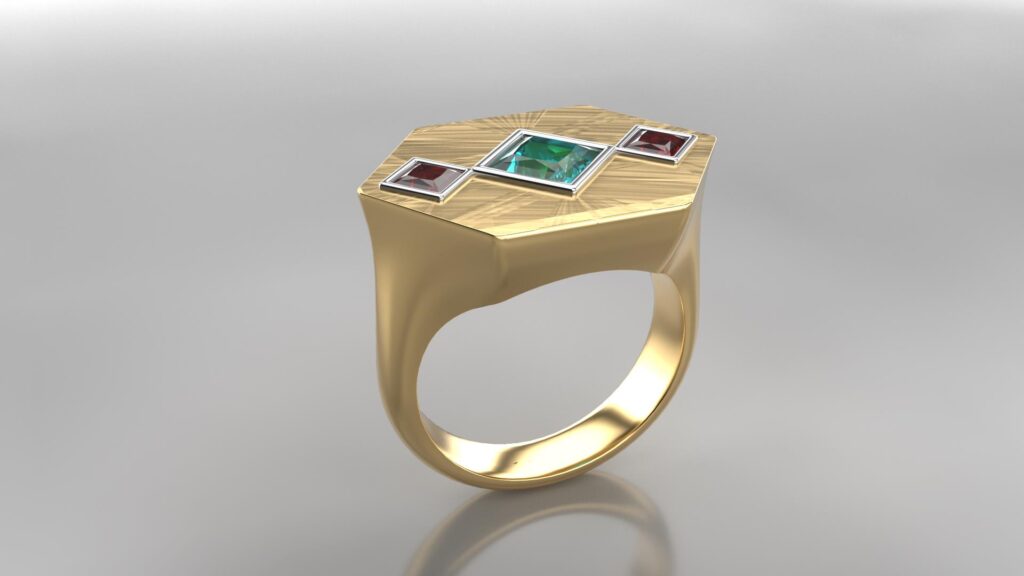

I made two more design changes. One design was a bit narrow for her taste and the other was a little wide. The stones seemed small for the top of the wider one. My client asked me to enlarge the aquamarine and reduce the ruby sizes. I used square brilliant cut stones (called “princess cut”), turned 45 degrees to the ring, to produce the effect of diamond shape stones. The last thing was to add a texture on the top of the ring.

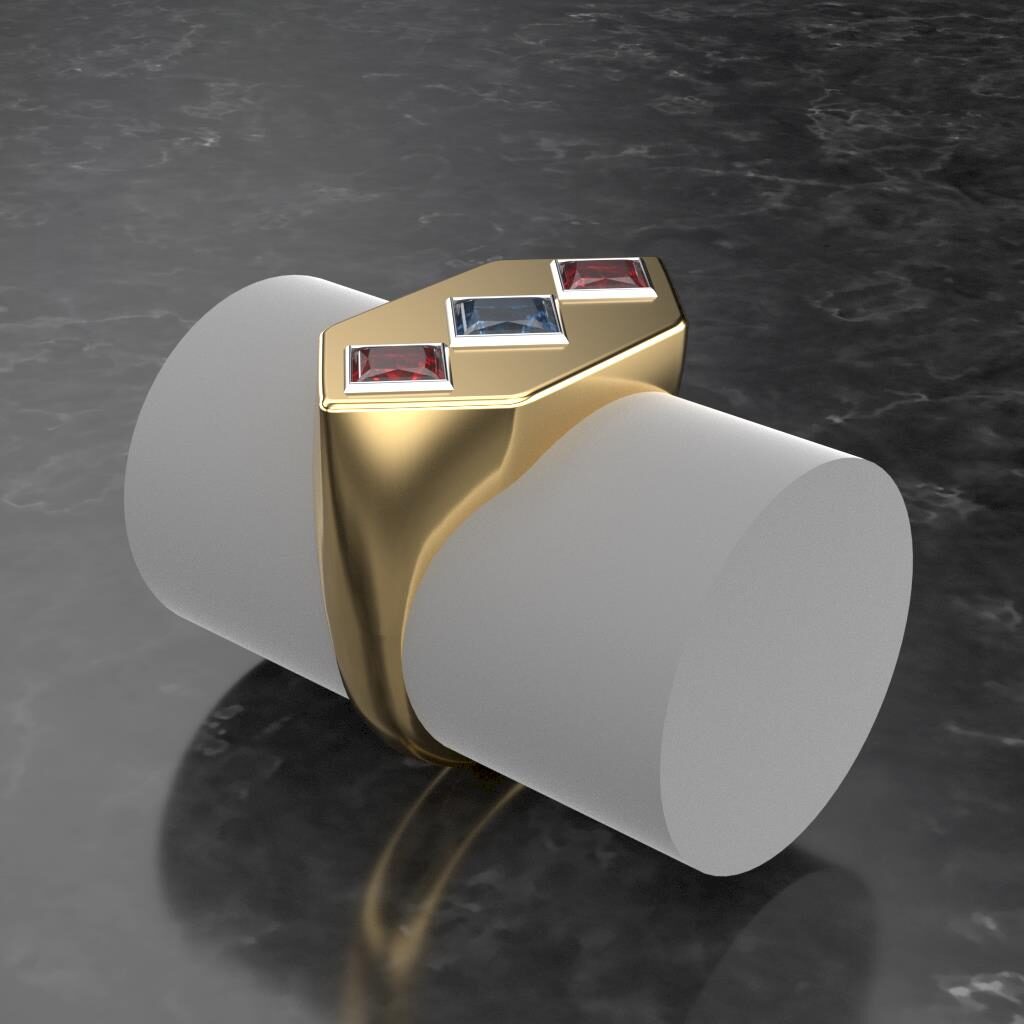

Semi-final Signet Ring – Side

Top View – Ring Too Narrow

Another look at the Design

This ring is getting close but the stones look a bit small for the width of the ring. We need a texture on top.

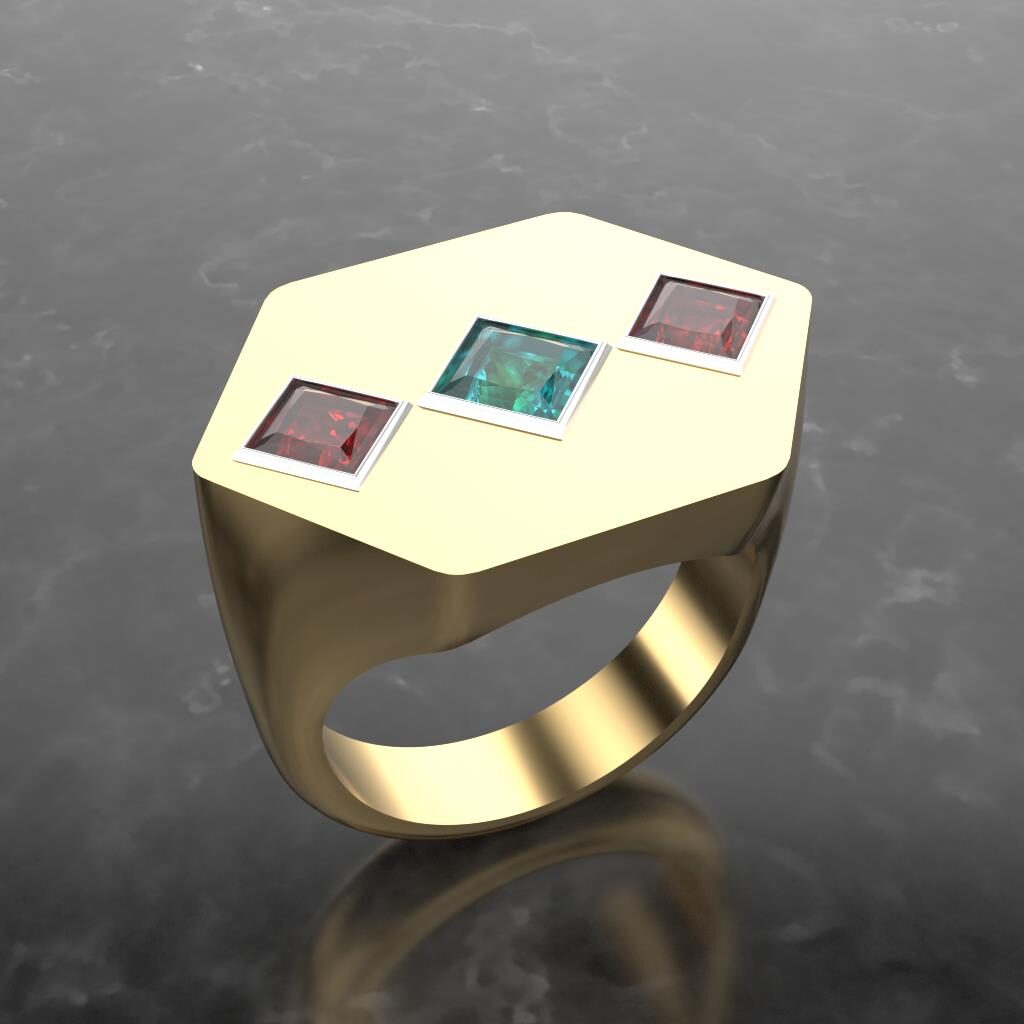

The Final Signet Ring Design

I finalized the design after one or two more emails. I sent a private YouTube video so she could see me turn the ring on my computer screen as I explained the design.

Custom Signet Ring – Final Design View

Custom Signet Ring – Side View

Custom Signet Ring – Another Side View

The Ring Fitting – 3D Model

I finally had the look she wanted. I made a 3D model of the signet ring out of a hard resin and the client had the opportunity to look at it along with the 3 gems I ordered. All was well. The whole process took 6 weeks. Many of my projects take between 4 and 6 weeks to complete properly.

I hope this has been helpful. Feel free to contact me if you think you would like my services. My email is dconger@congersjewellers.com ~ Dave Conger.